It depends greatly upon what kind of sausage it is and what kind of casing that is used. Natural Casings are the sub-mucosa layer of the intestines of pig, sheep, cattle and sometimes horses and the intestines were previously flushed, scraped and cleaned by hand, more recently, machinery has been used for large scale production. Natural casings breathe, allowing smoking and cooking flavors to permeate the casing and infuse the meat, giving the sausage a rich, even flavor throughout. Natural casings have unique natural curves and sheen, with rounded ends where the sausage is linked giving the sausage visual appeal.

Artificial casings are made of collagen, cellulose, or even plastic and may not be edible. Artificial casings from animal collagen can be edible, depending on the origin of the raw material. Collagen casings are mainly produced from the collagen in beef or pig hides, and the bones and tendons. It can also be derived from poultry and fish. They have been made for more than 50 years and their share of the market has been increasing.

Usually the cost to produce sausages in collagen is significantly lower than making sausages in gut because of higher production speeds and lower labor requirements. The latest generation of collagen casings are usually more tender than natural casings but do not exhibit the “snap” or “bite” of natural casing sausages. The biggest volume of collagen casings are edible, but a special form of thicker collagen casings is used for salamis and large caliber sausages where the casing is usually peeled off the sausage by the consumer. Collagen casings are less expensive to use, give better weight and size control, and are easier to run when compared to natural casings.

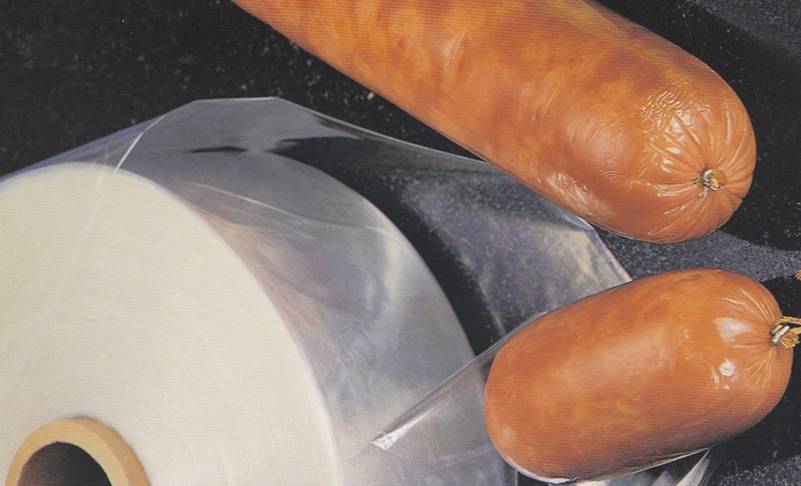

smokable casings

Cellulose, usually from cotton linters or wood pulp, is processed to make viscose, which is then extruded into clear, tough casings for making wieners and franks. They also are shirred for easier use and can be treated with dye to make red hots. The casing is peeled off after cooking, resulting in skinless franks. Cellulosic viscose solutions are combined with wood or for example abaca pulp to make large diameter fibrous casings for bologna, cotto salami, smoked ham and other products sliced for sandwiches. This type is also permeable to smoke and water vapor. They can be flat or shirred, depending on application, and can be pretreated with smoke, caramel color, or other surface treatments.

Plastic Casings are not eaten. They also can be flat or shirred. Generally, smoke and water do not pass through the casing, so plastic is used for non-smoked products where high yields are expected. The inner surface can be laminated or co-extruded with a polymer with an affinity for meat protein causing the meat to stick to the film, resulting in some loss when the casing is peeled, but higher overall yield due to better moisture control.

If necessary, please contact the Single-Clipper For Natural Casings Wholesaler