Sausages are a mixture of ground meat, fat, seasonings, and sometimes fillers that are packed into casings and then bound or twisted at intervals to form individual links. Traditionally, linked sausages were stuffed into natural casings made from animal intestines, but artificial casings are also available on the market, and today, most commercial sausages use synthetic casings. Before you make your own sausage, or just want to know what you're eating, Sausage Casing Manufacturers takes you through the differences between natural and artificial casings.

Sausage Casing

Natural casings

The origins of natural casings probably began around 4000 B.C. when cooked meat was stuffed into the stomachs of goats, but today's natural casings are made from the submucosa, a layer of farm animal intestines. The intestines come mainly from pigs, cows, goats, sheep, and sometimes a horse. This method of wrapping sausage has been around for centuries - although machines have replaced the need to clean the intestines by hand before use - and is the only form of wrapping available for organic sausage production.

The benefits of Natural Sausage Casings are flavor and visual appeal. Because natural casings breathe, they give the sausage a deeper, richer flavor - smoky and culinary flavors that penetrate the casings and infuse the meat. Because the casings are all-natural, the sausages have a very natural appearance, with some irregularities in shape and size.

Synthetic Sausage Casing

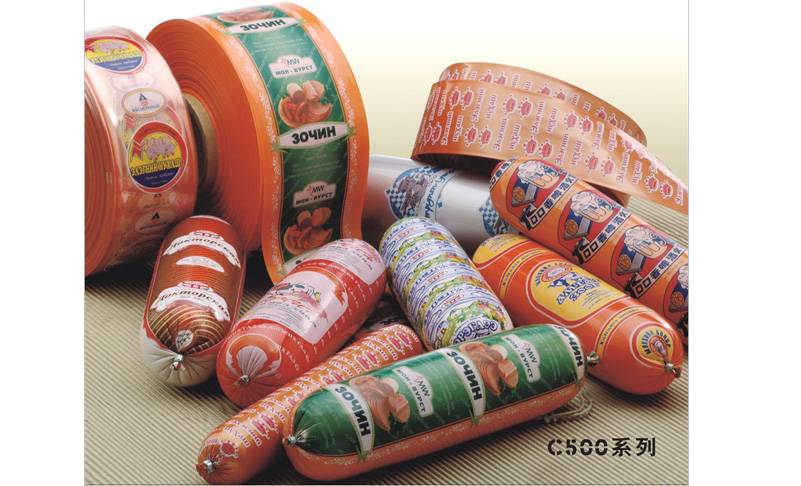

Artificial sausage casings can be made from materials such as collagen, cellulose and plastic, and are not always edible. Collagen casings have been around the longest and are made from animal collagen, mainly from the skins of cattle and pigs. Sometimes it also includes bone and tendon, and the casing can be made from poultry and fish. As an inexpensive option, collagen casings are easier to use than natural casings because they provide better control over the weight and size of the sausage.

Cellulose casings are made from viscose, a material composed of cellulose from wood pulp or cotton lint. These casings are strong and flexible and permeable to smoke; they can be peeled off after cooking. The plastic casings are not edible and are used for non-smoked, high-yield products because they are impermeable to water.

Some synthetic casings require soaking in hot tap water prior to use and need to be pierced with the tip of a knife to eliminate air pockets before stuffing. The advantages of using synthetic casings are strength and uniformity.

Alternative casings

If you do not have access to natural or synthetic casings, or just do not want to use them but still want to make sausage links, you can make casings from strips of muslin. To form a casing about 1.5 inches in diameter, cut strips about 6 inches wide and 16 inches long. Fold lengthwise and sew the edges together to form the tube.

If you are not using casings at all, you can still form links by rolling the mixture in aluminum foil or plastic wrap and refrigerating until firm. You will need to add a binder to the sausage mixture, usually 5% to 10% of the mixture, to prevent the meat from separating during cooking.

We also have a Clipping Machine available, please feel free to contact us if you need it!